How the Investment Casting Process Works?

Our Step-by-Step Investment Casting Process

Investment casting involves a series of carefully controlled steps that transform a wax pattern into a durable, high-precision metal component. Here’s how we do it at Invent Cast:

Wax Pattern Creation

High-quality wax replicas of the part are produced using precision tooling or 3D-printed molds.

Pattern Assembly

Shell Building

Dewaxing

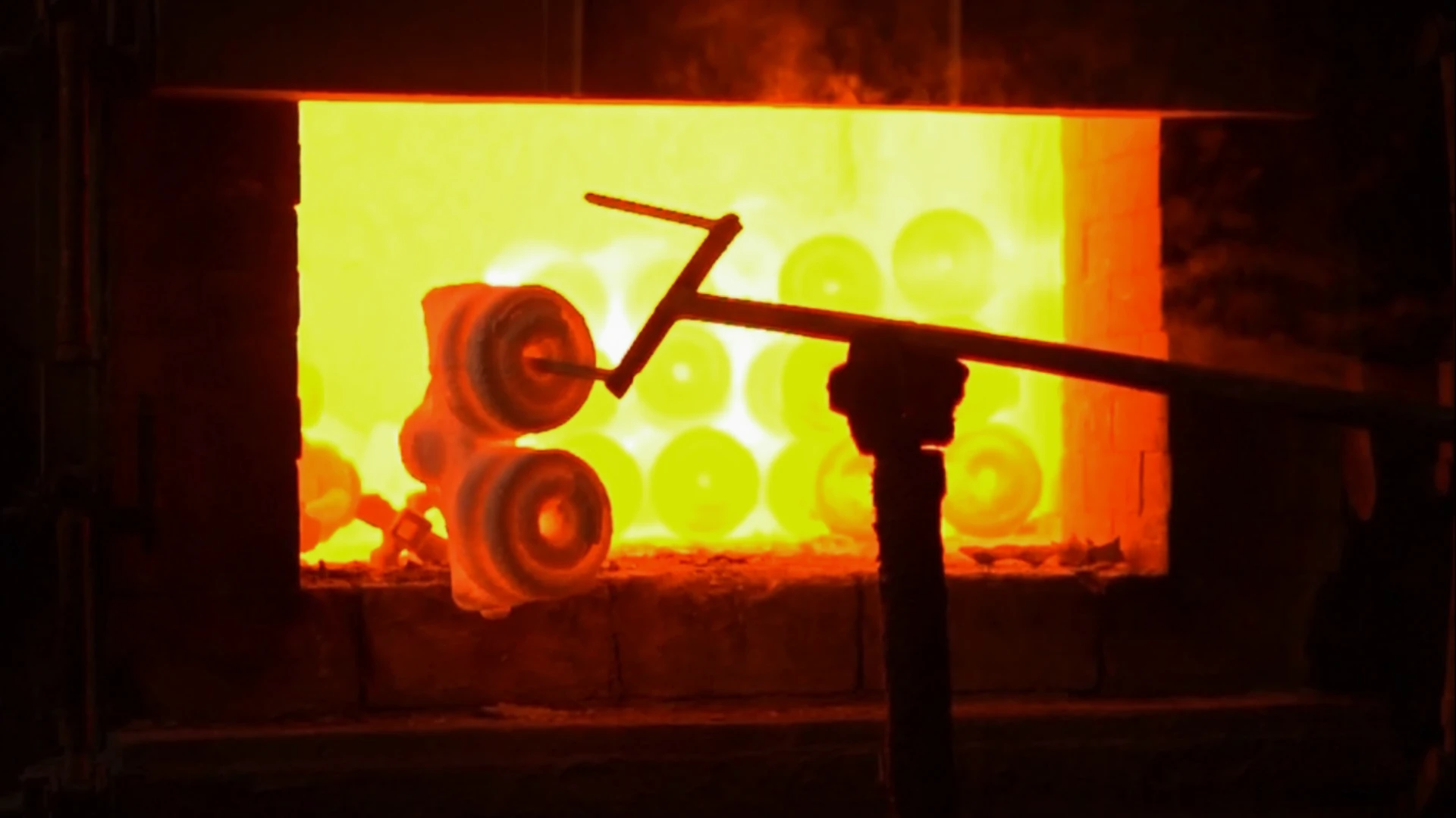

Shell Firing

Metal Pouring

Cooling & Shell Removal

Machining

Final Inspection & Dispatch

…and what you get

Advantages of Our Process

Custom tooling built by our own engineers ensures better quality and faster turnarounds.

We regularly achieve tolerances as low as ±0.1mm, suitable for complex assemblies.

Shell quality and pouring control allow us to deliver finishes as good as 3.2 Ra, reducing machining time.

Stainless steel, carbon steel, duplex, nickel alloys — all cast with optimized parameters and performance reliability.

Our process controls and digital tracking ensure repeatability, especially for high-volume production.

Streamlined shell-building and in-house pattern making cut project timelines significantly.

Invent Cast delivers precision-engineered components through advanced investment casting, forging, and sand casting—serving critical industries with unmatched reliability.