High-Precision General Engineering Castings Built to Perform

At Invent Cast, we specialize in manufacturing precision castings that meet global performance and safety standards. Built for strength, accuracy, and durability, our castings support a wide range of engineering applications where reliability is critical.

- Serving clients across USA, Europe, and India with precision-engineered components.

- ✼

- Delivering high-tolerance metal parts with complex geometries and repeatable accuracy.

- ✼

- From prototyping to high-volume production, all under one roof.

- ✼

- Serving clients across USA, Europe, and India with precision-engineered components.

- ✼

- Delivering high-tolerance metal parts with complex geometries and repeatable accuracy.

- ✼

- From prototyping to high-volume production, all under one roof.

- ✼

- Serving clients across USA, Europe, and India with precision-engineered components.

- ✼

- Delivering high-tolerance metal parts with complex geometries and repeatable accuracy.

- ✼

- From prototyping to high-volume production, all under one roof.

- ✼

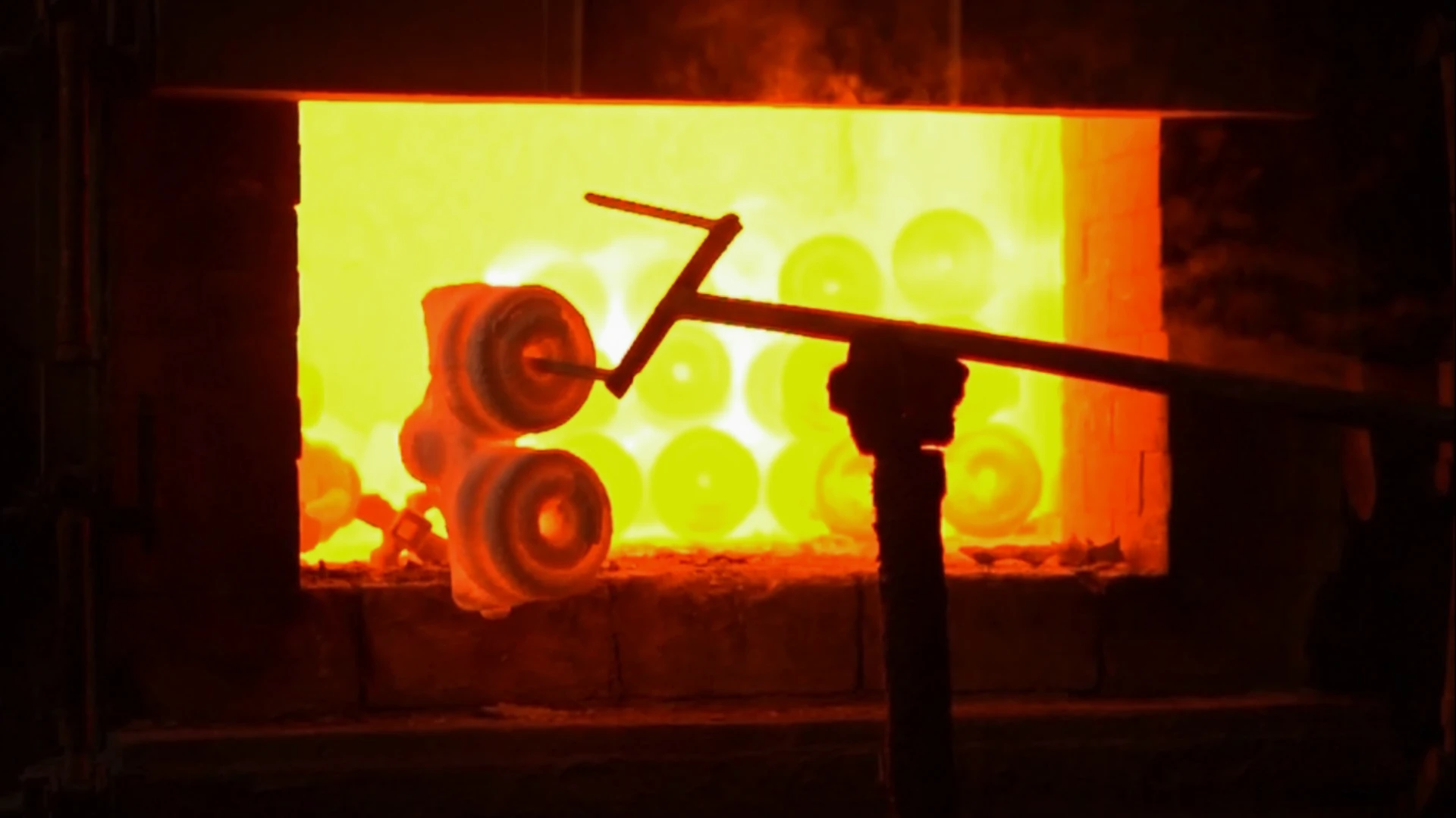

Manufacturing Process

Our castings are produced through a precise and controlled process to ensure high quality, durability, and dimensional accuracy.

Pattern Making: Creating accurate patterns for the desired casting shape.

Mold Preparation: Forming molds using high-quality materials for dimensional precision.

Melting & Pouring: Melting metal alloys and pouring into prepared molds under controlled conditions.

Cooling & Shakeout: Allowing castings to solidify, then removing them from the molds carefully.

Finishing & Inspection: Surface cleaning, machining, and thorough quality checks to meet engineering standards.

Our General Engineering Casting Range

| General Engineering Casting Technical Data | |

|---|---|

| R&D | Software: Solidworks, CAD, Procast, Pro-e |

| Lead Time for Development and Samples: 25 to 35 days | |

| Molten Metal | Carbon Steel, Alloy Steel, Tool Steel, Heat Resistant Steel |

| Stainless Steel (Ferritic, Martensitic, Austenitic, Duplex, Precipitation Hardening) | |

| Non-Ferrous Alloys: Aluminium, Copper, Nickel, Cobalt | |

| Metal Standard | ISO, GB, ASTM, SAE, GOST EN, DIN, JIS, BS |

| Material for Mold / Shell | Silica Sol (Precipitated Silica) |

| Water Glass (Sodium Silicate) | |

| Mixtures of Silica Sol and Water Glass | |

| Technical Parameter | Piece Weight: 2 gram to 200 kilogram |

| Max Dimension: 1,000 mm for Diameter or Length | |

| Min Wall Thickness: 1.5 mm | |

| Casting Surface Roughness: Ra 3.2–6.4, Machined Surface: Ra 1.6 | |

| Tolerance of Casting: VDG P690, D1/CT5-7 | |

| Tolerance of Machining: ISO 2768-mk/IT6 | |

| Core Material: Ceramic Core, Urea Core, Water Soluble Wax Core | |

| Heat Treatment | Normalizing, Tempering, Quenching, Annealing, Solution Treatment, Carburization |

| Surface Treatment | Polishing, Sand/Shot Blasting, Zinc Plating, Nickel Plating, Oxidation, Phosphating, Powder Coating, Anodizing |

| Dimension Testing | CMM, Vernier Caliper, Inside Caliper, Depth Gauge, Height Gauge, Go/No-Go Gauge, Special Fixtures |

| Chemical Inspection | Chemical Composition Analysis (20 Elements), Cleanliness Check, X-ray Inspection, Carbon-Sulfur Analysis |

| Physical Inspection | Dynamic & Static Balancing, Mechanical Properties (Hardness, Yield Strength, Tensile Strength), Elongation |

| Production Capacity | More than 250 tons per month, over 3,000 tons annually |

Testing & Compliance

We ensure every casting meets global quality and safety standards through rigorous testing and strict compliance checks.

Dimensional Verification: Using CMM, calipers, and gauges for precise measurements.

Non-Destructive Testing (NDT): Dye penetrant, ultrasonic, and radiographic inspections to detect defects.

Mechanical Testing: Hardness, tensile strength, yield strength, and impact resistance checks.

Metallurgical Analysis: Microstructure evaluation to ensure alloy integrity and performance.

Standards Compliance: ISO, ASTM, DIN, and other international standards adherence.

- Serving clients across USA, Europe, and India with precision-engineered components.

- ✼

- Delivering high-tolerance metal parts with complex geometries and repeatable accuracy.

- ✼

- From prototyping to high-volume production, all under one roof.

- ✼

- Serving clients across USA, Europe, and India with precision-engineered components.

- ✼

- Delivering high-tolerance metal parts with complex geometries and repeatable accuracy.

- ✼

- From prototyping to high-volume production, all under one roof.

- ✼

- Serving clients across USA, Europe, and India with precision-engineered components.

- ✼

- Delivering high-tolerance metal parts with complex geometries and repeatable accuracy.

- ✼

- From prototyping to high-volume production, all under one roof.

- ✼